Your cart

There are no more items in your cart

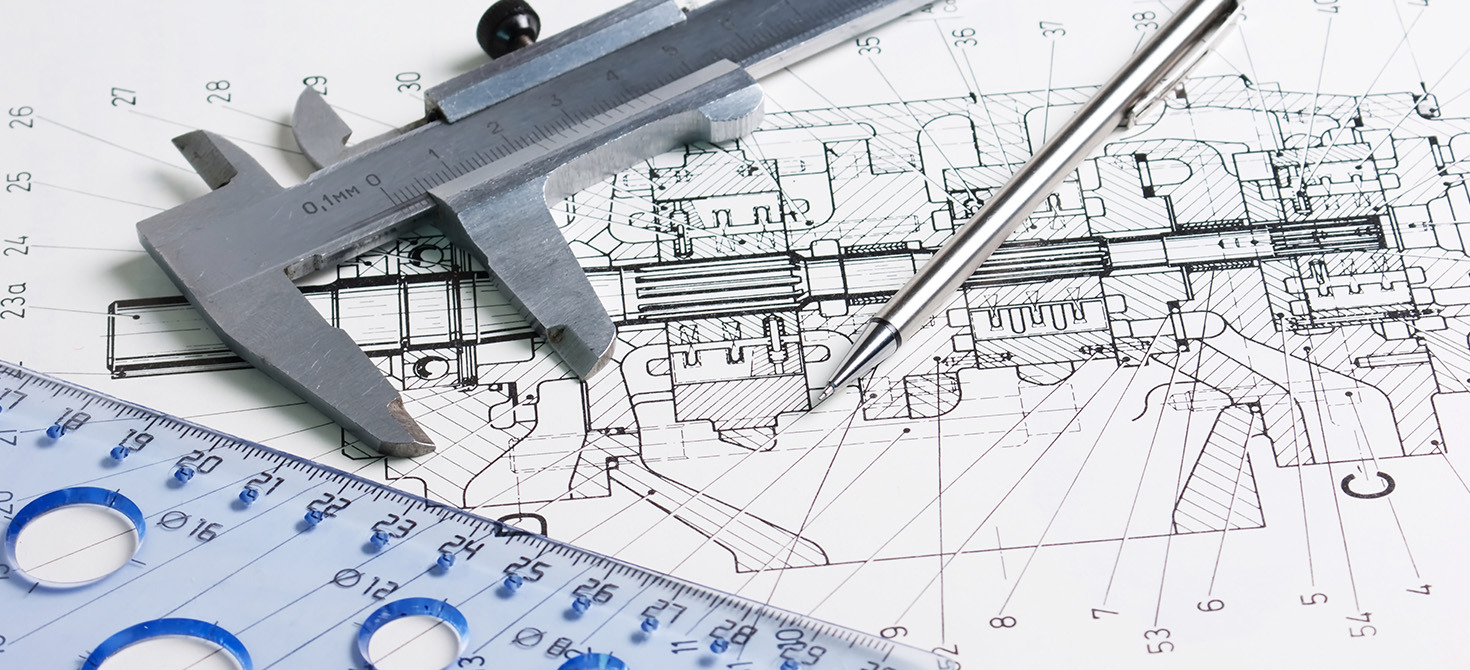

The quality and effectiveness of a job depends on the precision with which it is done.

Precisely for this reason, to ensure that the work carried out has an excellent result, it is necessary to use measuring instruments and precision that can calculate to the thousandth any type of measurement.

Analog or digital and useful for measuring depth, temperature, mass, etc. .... there are various types of measuring instruments on the market, suitable for every need.

Characteristics of a measuring tool

Differing in mode and effectiveness of use, the cost of measuring tools differs in the characteristics and capabilities of each individual tool.

The values to be considered are:

- The maximum capacity: this is the largest value of the quantity that the tool can measure. The maximum capacity of a measuring tool must be chosen in relation to the object to be measured.

- Accuracy: an indication of the quality of the instrument. The precision of a measuring instrument derives from its ability to provide values equal to those of another instrument, and from its ability to obtain the same measurement, repeated several times, on the same object.

- Sensitivity: the opposite of range. Sensitivity is the smallest value of the quantity that an instrument can measure.

- Readiness: is the speed of response that a measuring instrument provides in the event of a change in the values of an object.

Some types of measuring instruments

- Abram’s cone: instrument used to measure the consistency of fresh concrete. Used for road work and foundations.

- The flat-parallel block: instruments used to adjust and calibrate length measuring devices. They are divided into 6 classes depending on the accuracy and use.

- The scale: an instrument that uses pressure to calibrate the weight of an object. The scale belongs to the mass measuring instruments.

- Caliper:

- The thickness gauge: an instrument used to check the space between two parts. The thickness gauge belongs to mechanical measuring instruments.

- Depth gauge: an instrument used for measuring the distance separating the head of the sliding part. The measuring range achieves high accuracy.

- Slide caliper: an instrument used for precise measurement of a length. The measuring instrument can be either analog or digital.

- Check gauge: an instrument used for checking and measuring a geometric shape or dimension.

- Thread Pad Gauge: an instrument used for measuring the pitch of a screw.

- Ruler: the best known of all measuring instruments. It is used to measure a length or trace a line.

- Protractor: both analog and digital, the protractor measures the amplitude of an angle.